|

One important difference between the British Army and the other ones entering into war in August 1914 was the fact it had recently participated to a conflict during the Boer Wars in South Africa, fighting a non conventional army however equipped with modern weapons. These campaigns learnings had consequences on British artillery evolution, as well as on the introduction of modern grenades, the very first one appearing in 1908. This 'Grenade Nr 1, General Service' equipped the British Expeditionary Corps participating to the fist battles on the continent.

The experience of the early trench fights induced the same need for every country : more grenades, and better ones ! As a consequence, improvised models were produced in parallel to the development of new reglementary ones.

The Mills grenade appearing in 1916 is one of the latter, and will be by far the best hand grenade of the WW1, continuing its international career until the 1970's.

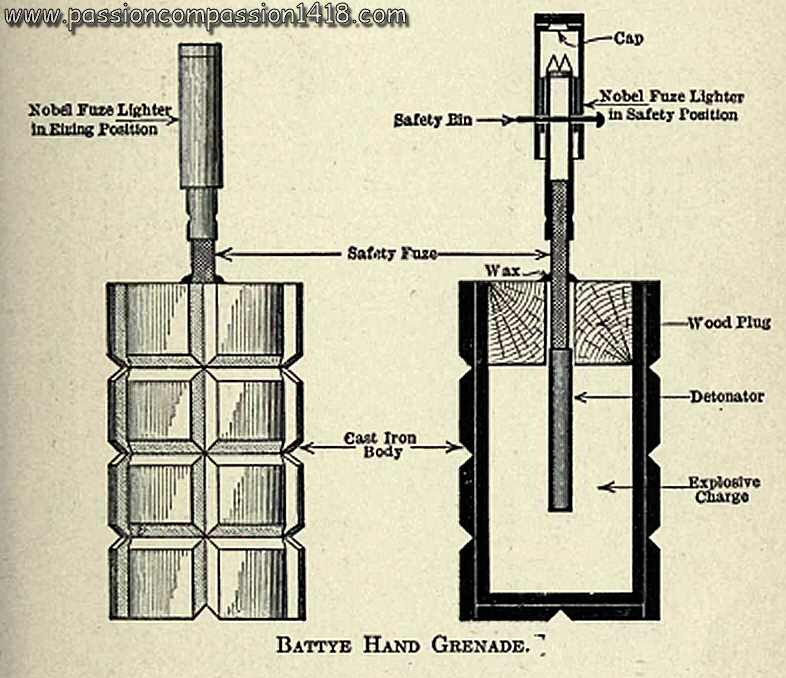

Battye hand grenade |

||

|

|

Just like most of the fighting nations armies, Great Britain Army had to compensate the lack of reglementary grenades at the beginning of the war by a parallel production of improvised weapons. The Battye grenade was born in 1915 and was an idea of a major named Battye, built on the basis of a simple prefragmented cylinder made in Bethune (France) by the thousands. The use of improvised grenades such as this one was forbidden at the end of 1915 in the British Army, because of too numerous accidents. Total weight 550 g including ammonal explosive load |

Battye grenade. |

Empty Battye grenade. |

|

|

||

Battye grenade - wartime scheme with a simple percussion igniter |

||

Return at the top of page |

||

Mills rifle and hand grenade |

||

|

|

Before the war start, two Belgian citizens - Albert Dewandre (an engineer) and the Captain Léon Roland (from the Compagnie Belge des Munitions Militaires) - designed the principles of this modern grenade : an automatic ignition system fully located inside the grenade body and therefore waterproofed. The start of the great war brutally stopped this invention development (the Captain Roland being capured by the Germans as a prisonner). But a talented English manufacturer, William Mills, who met Dewandre at the end of 1914, made the theoretical concept possible, and introduced a patent as soon as February 1915.

|

N°5 MkI Mills grenade. |

N°5 MkI Mills grenade, front view with the filling hole brass plug. |

|

|

|

|

N°5 MkI Mills grenade. Bottom view, base plug removed showing the detonator. |

N°5 MkI Mills grenade. Base plug detail with manufacturer marks (october 1915 - Calthorpe Motor) |

|

|

||

N°5 MkI Mills grenades. The left body has been observed in Flanders Fields, near Hooge. |

||

|

||

N°5 MkI Mills grenades. Wartime scheme. |

||

Return at the top of the page |

||

N°34 hand grenade |

||

|

|

The small and handy German egg grenade '('Eierhandgranate')' inspired the British designers who introduced in the end of 1917 a copy made of a cast iron body and a simple percussion igniting plug, with a 5 seconds delay. This new Hand Grenade N°34 is known in 4 successive variants :

|

Handgrenade N°34 Mk III - view showing the charge loading hole plug |

Handgrenade N°34 Mk III - igniter threaded hole |

|

|

||

Handgrenade N°34 Mk III - dismantled percussion igniter, no detonator |

||

Return at the top of the page |

||

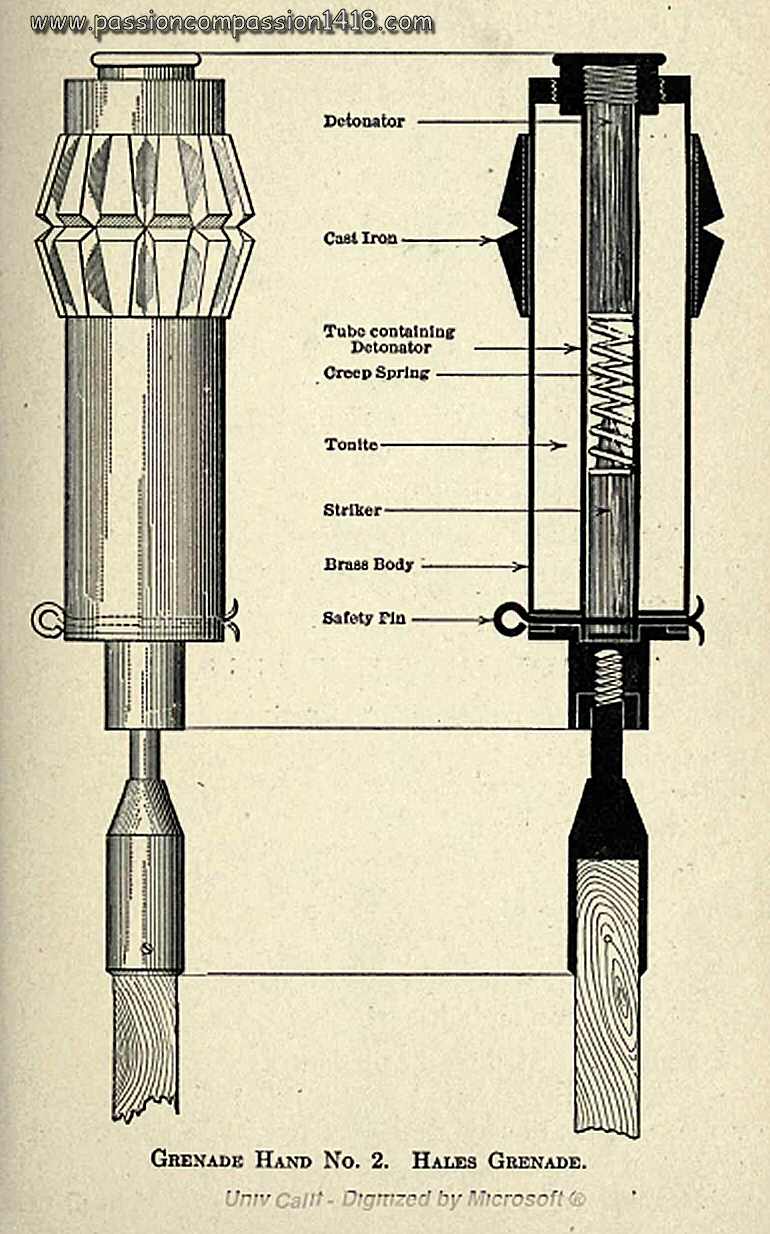

Percussion rifle and hand grenade MARTEN HALE 'Mexican' |

||

|

Using the same technological basis than the reglementary percussion hand grenade N°1 MkI, MKII and MkIII General Service made by the Woolwich Royal Laboratory (1908) issued from the Boer war experience, the private company Marten Hale Cotton Powder Ltd was already manufacturing a percussion grenade for the Mexican Army in 1907. Facing the insufficient production of the reglementary grenade N°1 compared to the British Army needs in 1914, the headquarters adopt this private grenade and name it the Rifle and hand grenade N°2 MKI (the French army will use it as well shortly). |

|

Rifle grenade N°2 Mk I reassembled. Markings : 'THE COTTON POWDER Co Ltd - HALES PATENT LONDON - 8 M/M - B'. The '8mm' means this item is the model adapted for use with French Lebel rifles. |

||

|

|

|

Rifle grenade N°2 Mk I. Detail of the body cut in two for trench art making. |

Rifle grenade N°2 Mk I. wo of them mounted as a war souvenir trench art item. |

|

|

||

Rifle grenade N°2 Mk I - wartime scheme. |

||

Return at the top of page |

||

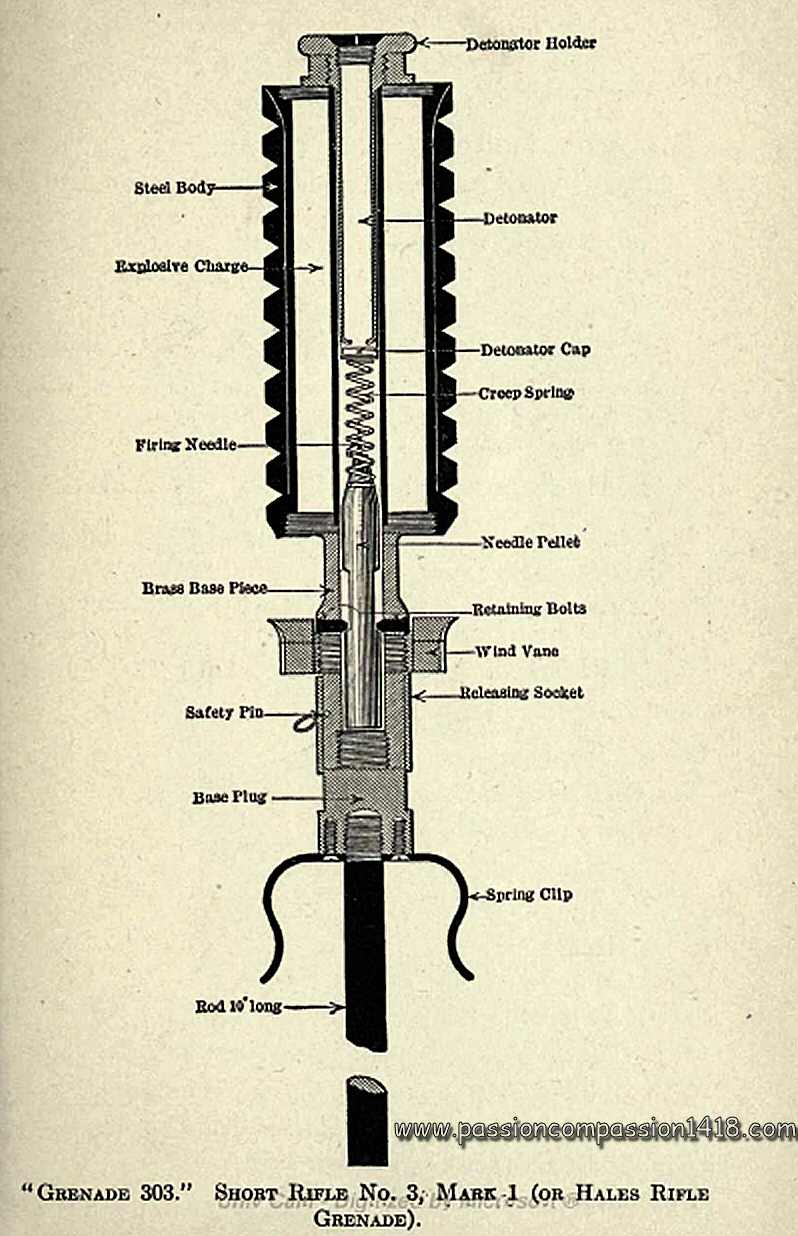

Rifle grenade N°3 |

||

|

Capitalizing the experience acquired with the manufacturing and use of the rifle grenade N°2, the company Marten Hale Cotton Powder Ltd designed a new percussion rifle grenade equipped with a much more sophisticated safety system, and a bigger lethal power. |

|

Rifle grenade N°3 Mk II. |

||

|

|

|

Rifle grenade N°3 Mk II. View on the wind vane, one of the two spring clips and the releasing socket still secured by the safety pin. |

Rifle grenade N°3 Mk II. View on the top cap, which was in fact the detonator holder. |

|

|

|

|

Rifle grenade N°3 Mk II. Markings on the wind vane : 'THE COTTON POWDER Co Ltd - LONDON - HALE'S PATENT'. |

Rifle grenade N°3 Mk II. Wartime scheme. |

|

Return at the top of page |

||

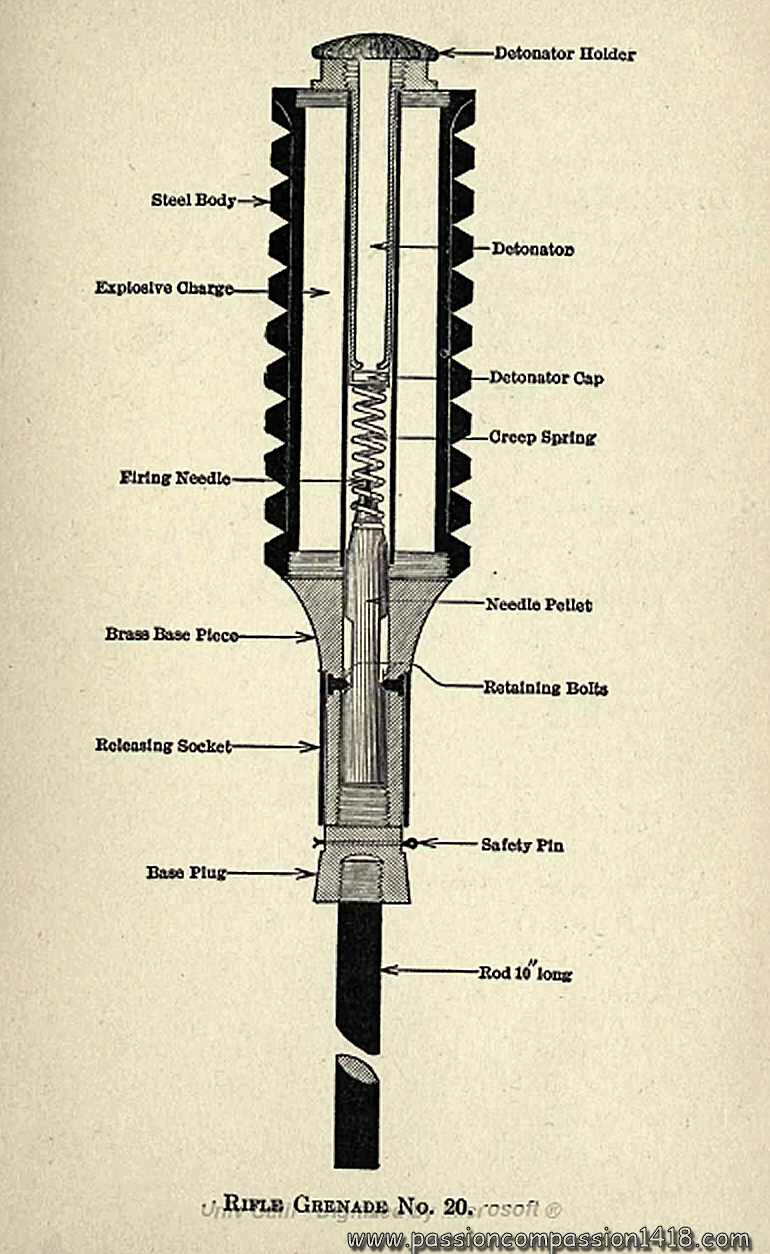

Rifle grenade N°20 |

||

|

As seen above on this page, the new rifle grenade N°3 inspired from the commercial percussion grenade Marten Hale appears in 1915. This design solved most of the safety issues associated to the rifle grenade N°2. However, if the ingenious mechanism based on the release of the safety chain by the in-flight air flow on a wind vane was efficient, it also induced too much manufacturing complexity and costs.

|

|

Rifle grenade N°20 Mk I |

||

|

|

|

Rifle grenade N°20 Mk I. Top view with the detonator holder plug unscrewed |

Rifle grenade N°20 Mk I. Plug top - markings 'G.T.L.' |

|

|

|

|

Rifle grenade N°20 Mk - Zoom on the base including the arming system. See the sliding socket retained by a safety pin. |

Rifle grenade N°20 Mk I - Wartime scheme |

|

Return at the top of page |

||

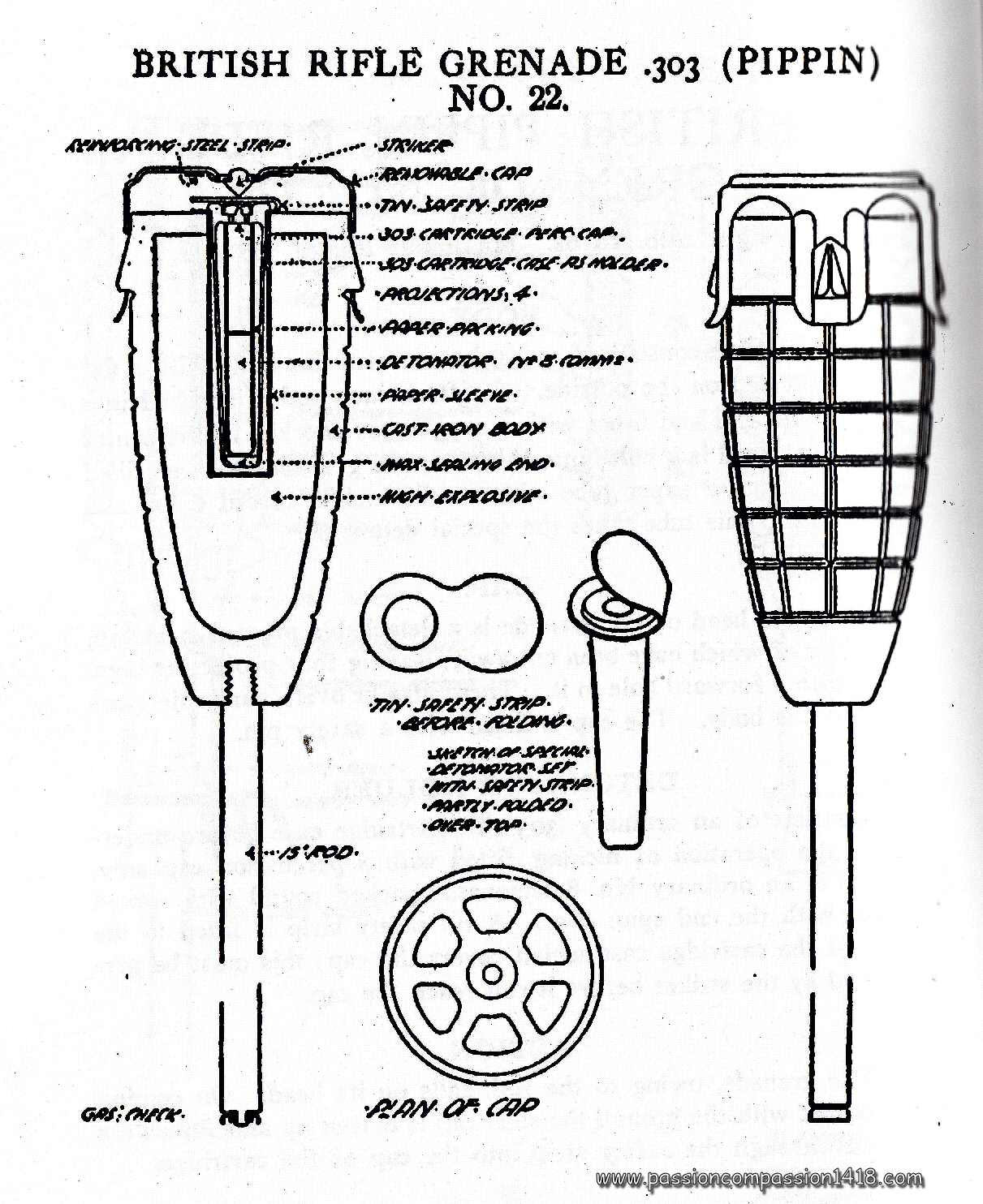

Rifle grenade N°22 'Pépin' |

||

|

From May 1915, the British Army organizes in Hazebrouck the manufacturing of prefragmented hand grenades having the shape of a grapefruit grain (in French 'Pépin') named 'Hand grenade Newton Pépin'. Dangerous, they will inspire the French grenade Citron Foug, as well as the British rifle grenade N°17 MkI (June 1917), that has been rapidly improved to become the rifle grenade N°22 Mk I. |

|

Rifle grenade N°22 |

||

|

|

|

Rifle grenade N°22, typical body shape (wine glass) |

Rifle grenade N°22, top view. |

|

|

||

Rifle grenade N°22. Wartime scheme. |

||

Return at the top of page |

||

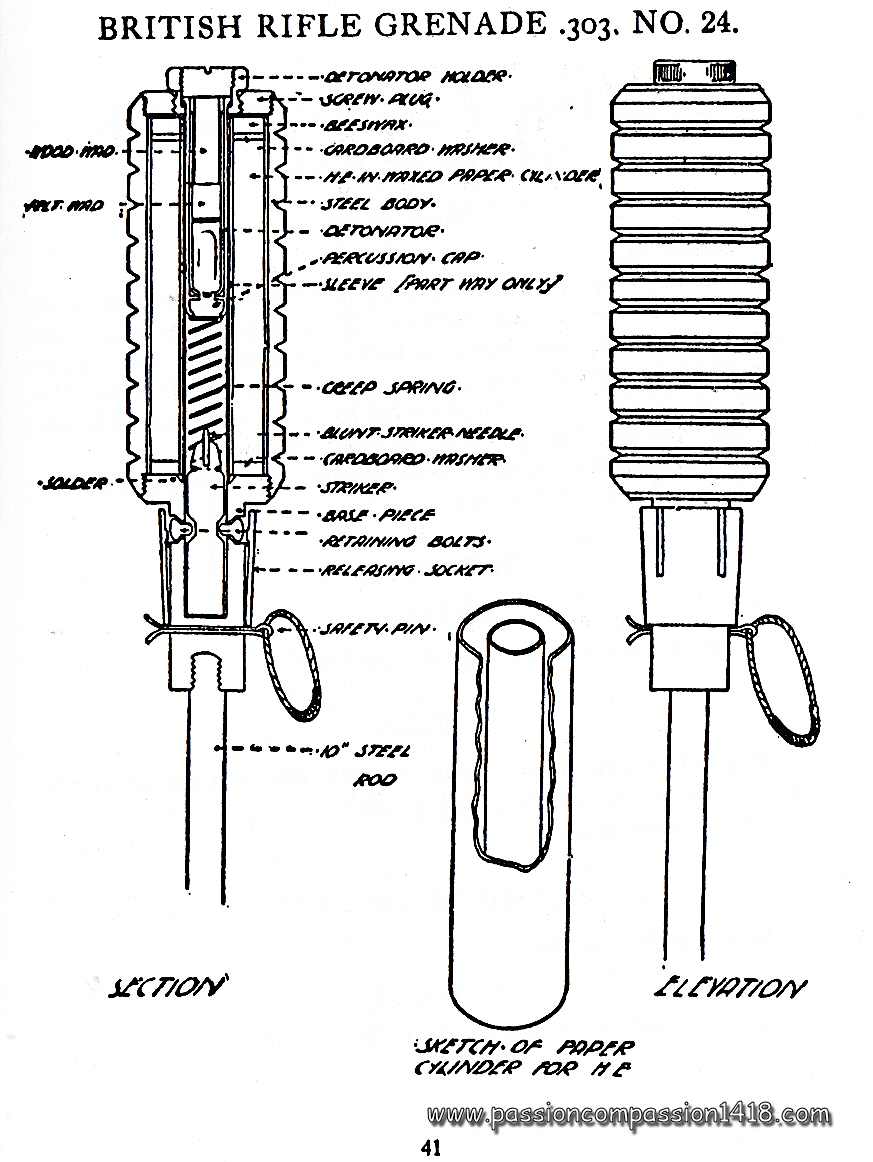

Rifle grenade N°24 |

||

|

|

The rifle grenade N°24 Mk I is another June 1917 simplification of the rifle grenades series N°3 and N°20. |

Rifle grenade N°24 Mk I. Transverse prefragmented body - Picture courtesy Luc Malchair |

Rifle grenade N°24 Mk I - Wartime scheme |

|

|

||

Rifle grenade N°24 Mk I prefragmented body |

||

|

||

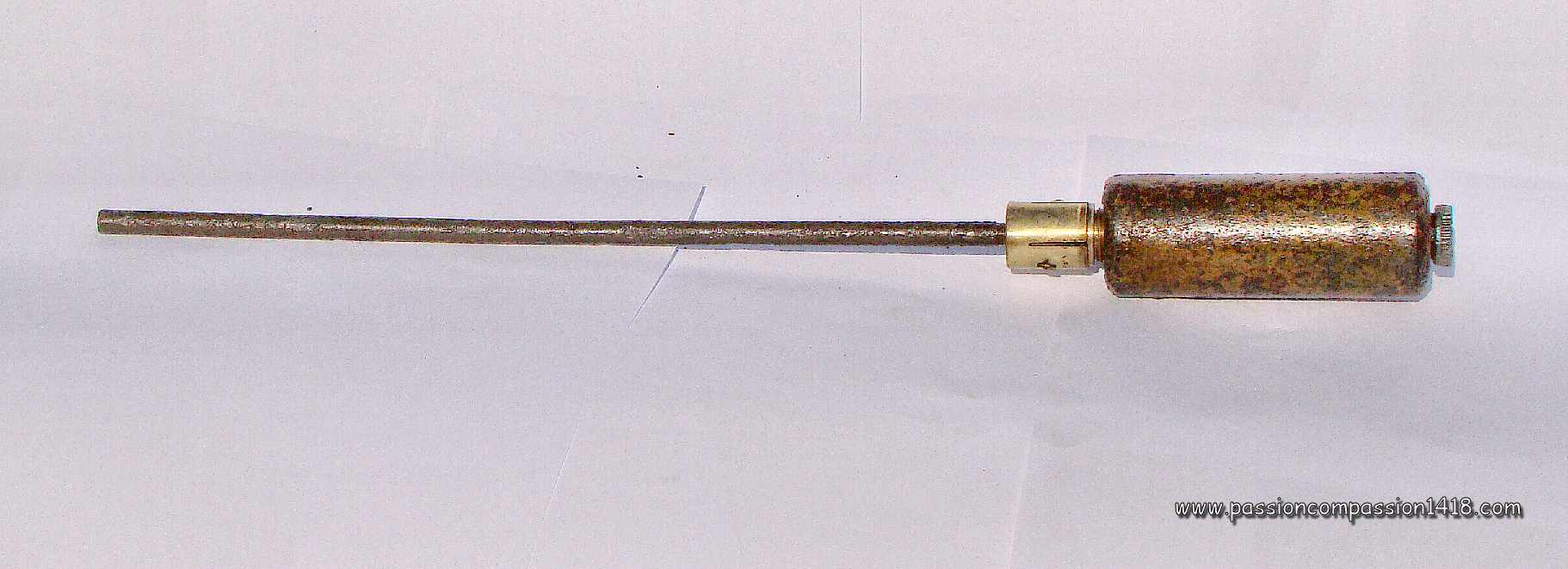

Rifle grenade N°24 Mk II smooth body |

||

|

|

|

Rifle grenade N°24 Mk II, tail body detail with safety pin |

Rifle grenade N°24 Mk II, top detail, unscerwed plug (lost) |

|

Return at the top of page |

||

Rifle grenade N°35 |

||

|

Ultimate evolution dated May 1918 of the prolific British rifle grenades family, the rifle grenade N°35 Mk I is a simplification of the rifle grenade Nr24 MkII, whose brass body has been shortened further and whose safety pin is passing through the sliding socket instead of below it. |

|

Rifle grenade N°35 Mk I, smooth body |

||

|

|

|

Rifle grenade N°35 Mk I, zoom on the shortened tail base, with safety pin |

Rifle grenade N°35 Mk I, top view. Markings 'Nr35 MKI - 1917 - W.S. & S. |

|

|

||

Rifle grenade N°35 Mk I. Dismantles grenade with bakelite plug, detonator tube, brass tail base showing the percussion pin tube and spring, safety socket and safety pin, and the steel rod. |

||

Return at the top of page |

||